One of the key aspects of glow-in-the-dark direct printing is the use of specialized inks containing phosphorescent pigments. These pigments absorb and store ambient light when exposed to it and then release this stored energy in the form of visible light in the dark. This creates a distinct and eye-catching luminescence. The direct printing process involves transferring these specially formulated inks onto various surfaces, such as paper, fabric, or plastic, through techniques like screen printing, offset printing, or digital printing. This versatility allows for the application of glow-in-the-dark effects to a wide range of products, from t-shirts and posters to packaging materials.

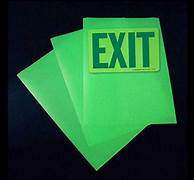

The applications of glow-in-the-dark direct printing are diverse and continue to expand. Beyond its use in promotional materials, this printing technique is often incorporated into safety signage and products, ensuring visibility in emergency situations or low-light environments. Additionally, it serves as a unique and attention-grabbing element in artistic projects, adding an extra layer of creativity and intrigue. As technology advances, the potential for more sophisticated and customizable glow-in-the-dark printing options grows, offering exciting possibilities for businesses and artists alike.